For our Senior Design Capstone project at UCLA, our team of seven built an autonomous, scalable farming system. There is a strong movement for young people to start growing their own locally sourced produce. A lot of them don’t often know where to begin and professional farmers and gardeners often have esoteric knowledge of soil conditions, sunlight, and optimum seasonal and growing conditions for a variety of different plants. Our team wanted to build a product that takes this intimidation away.

Our distinguishing feature is that this system is portable and scalable to any plot size. A module carries out functions of planting seeds, watering, and maintaining spinach plants over several weeks autonomously using various sensors and Arduino programming.

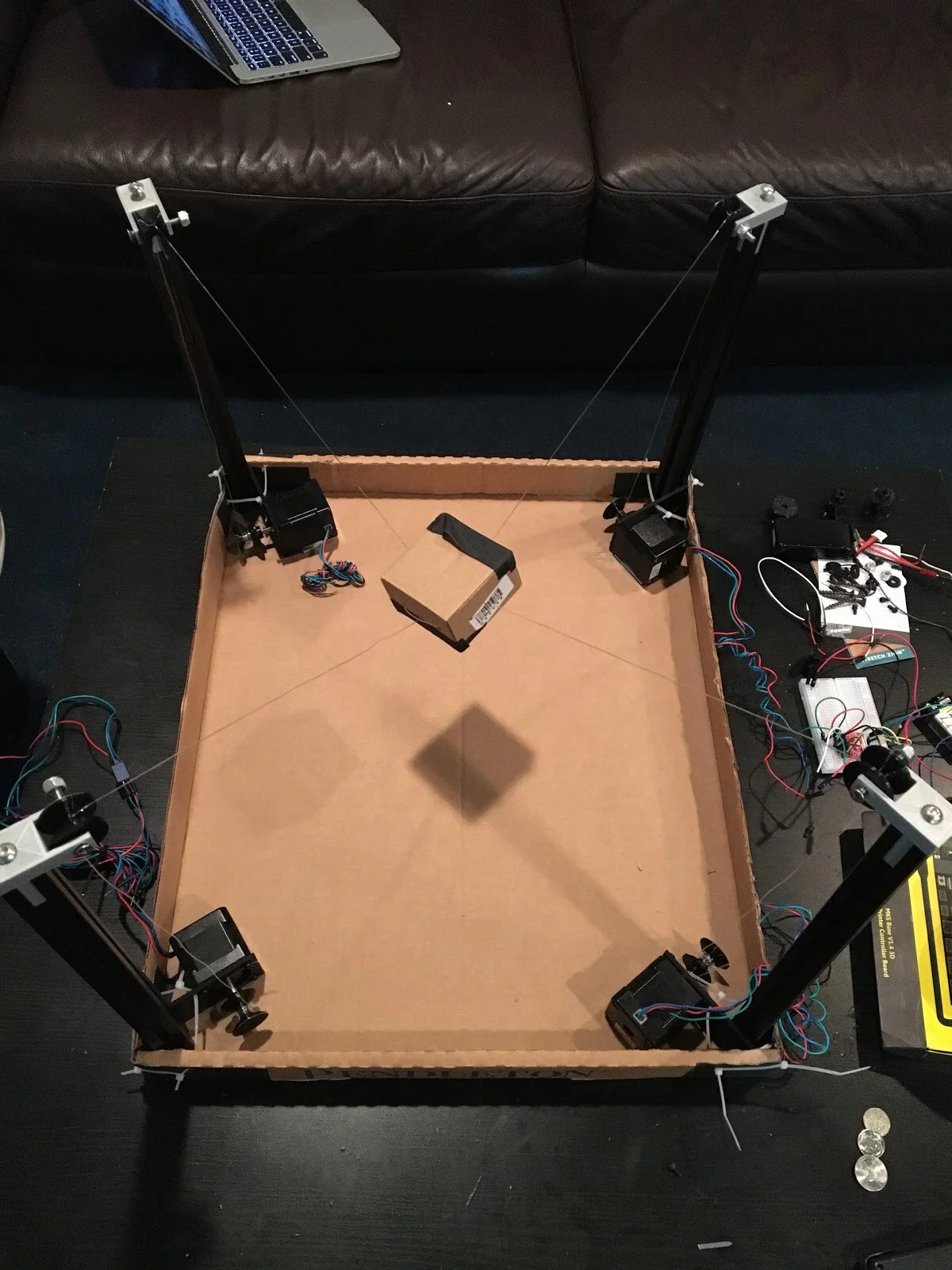

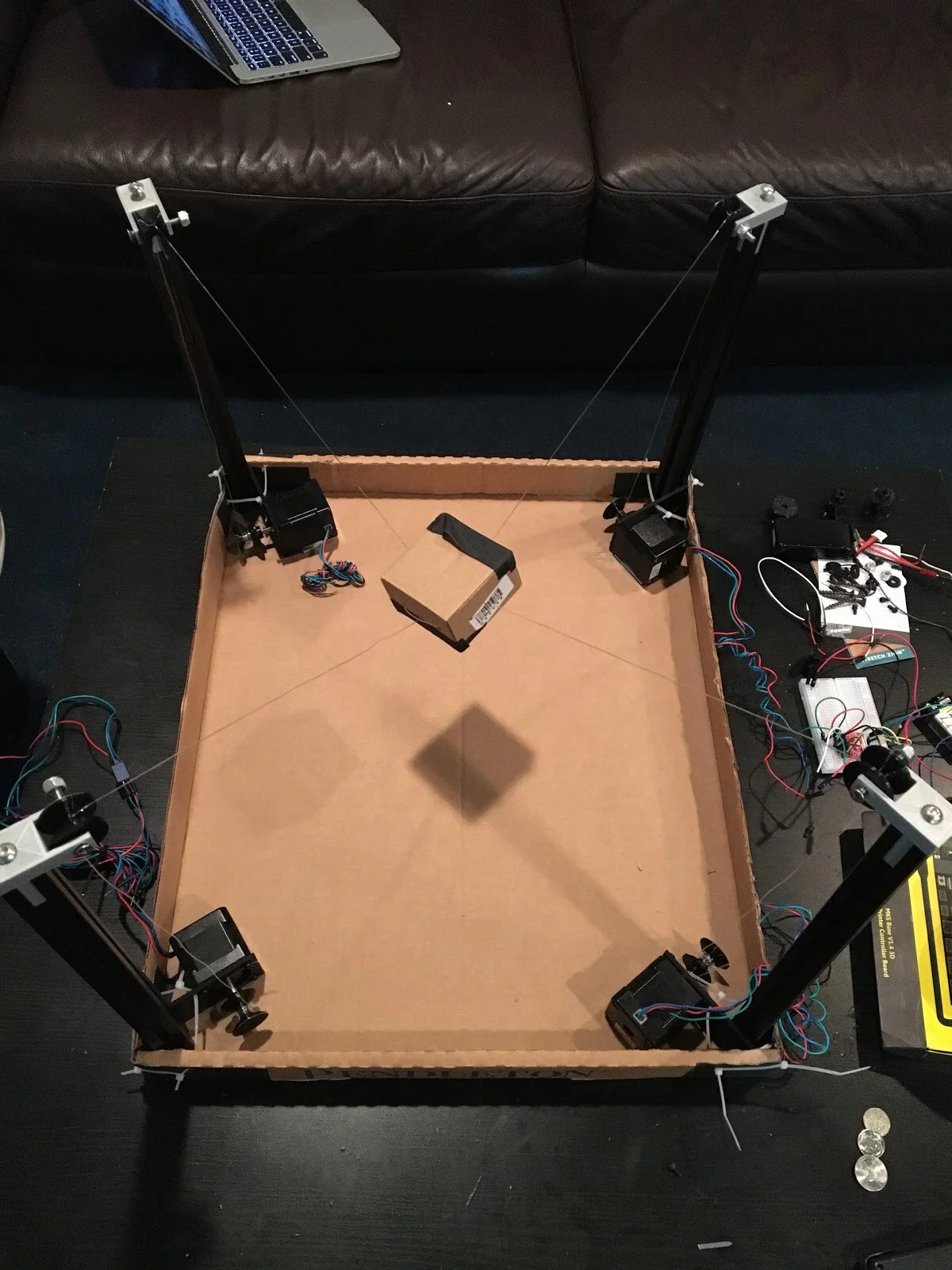

Before any CAD development was carried out, we did some preliminary prototyping using floss, thread, cardboard, and 80/20 to emulate the motion we desired of the module in a grid system after having researched SpiderCAM, and the Delta 3D printer motions. The SpiderCAM captures high resolution shots in stadiums by utilizing four motorized winches positioned at each corner at the base of the covered area, each of which controls a Kevlar cable connected to a gyro-stabilized camera-carrier, or dolly. By controlling the winding and unwinding of the cables, the system allows the dolly to reach any position in the three-dimensional space. The Delta 3D printer uses trigonometric functions based on the angles that three arms create to determine the precise location of the print head within the 3D print space. Both navigation and locating systems fascinated us and served as an inspiration for Operation Dionysus.

This module is attached to four cables that route from four towers separate of our 4’x4’ testing soil bed that comprise the kinematic system. To save on costs for other parts of the system, we decided to use boxes that would house sandbags to weigh the PVC poles down instead of creating concrete bases.

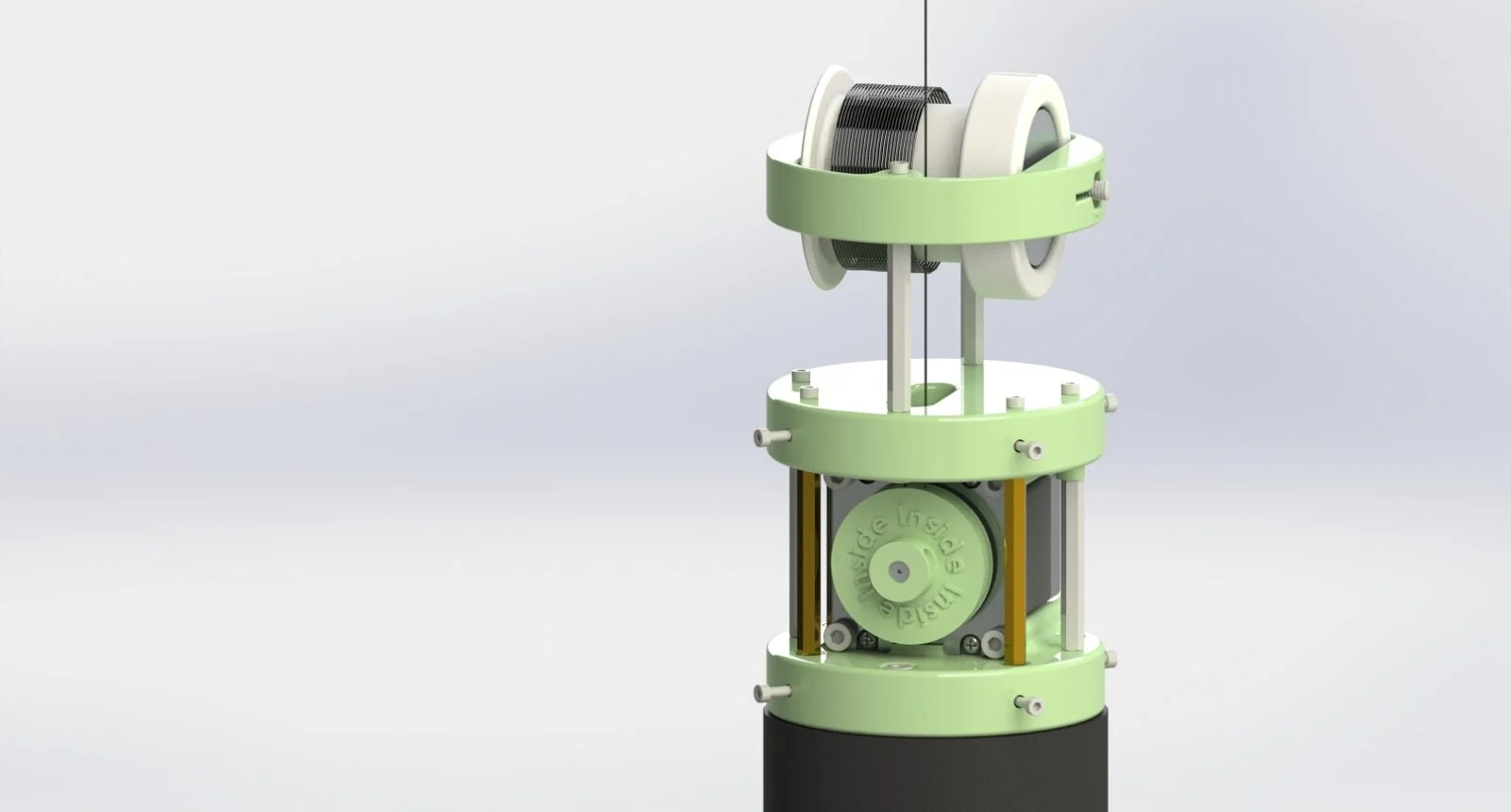

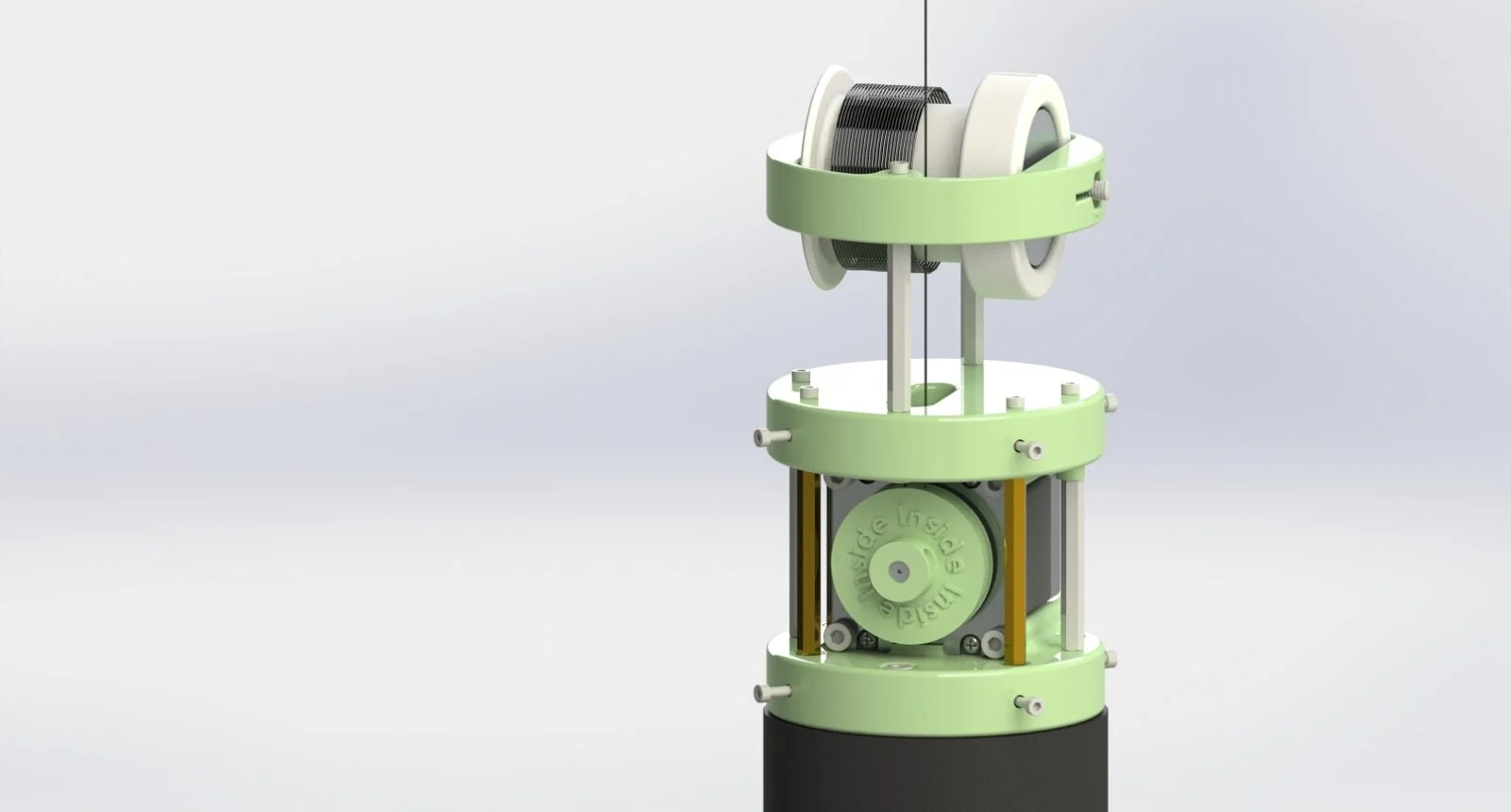

The poles of this system are dual purpose, enclosing the stepper motors that drive the kinematics of the system, and functioning as portable structures allowing for this system to be scalable. These poles slip fit onto a 4” wide Delrin cylinder that is bolted to a container that can be weighed down. Inside these poles are two main components, the NEMA-23 stepper motor and spool assembly on the bottom, and the eyebolt at the top to guide the string (not pictured). NEMA-23 stepper motors provide the holding torque to successfully navigate the module in a Cartesian coordinate space.

The second model was a miniature of the final intended version. It was very useful to be able to test our Arduino code and have a proof of concept to know that the final design would work as planned.

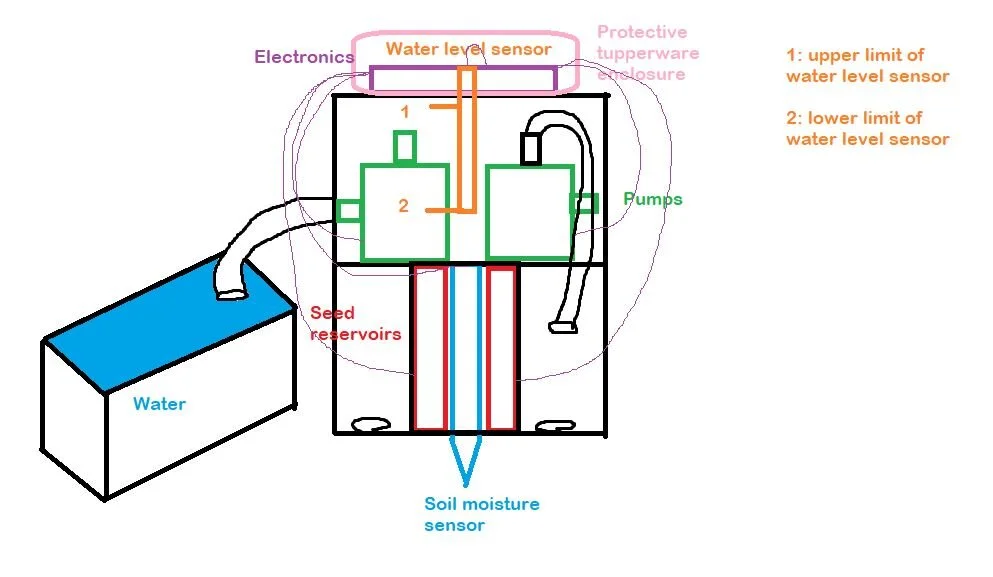

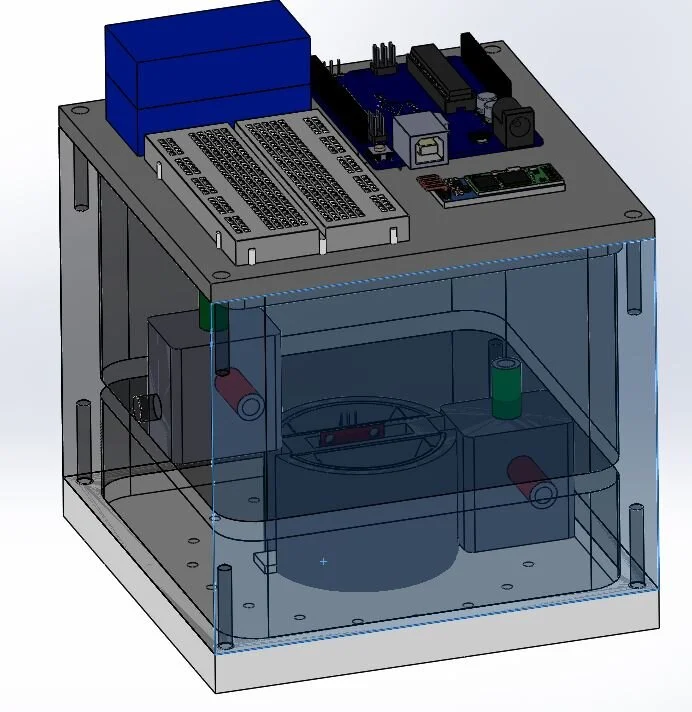

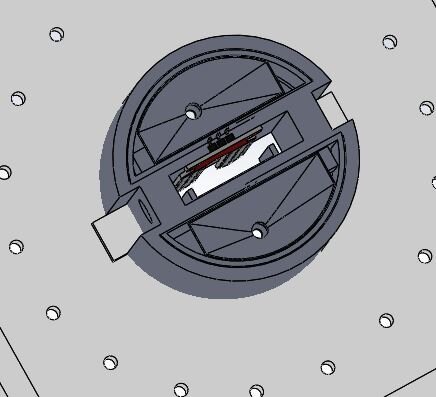

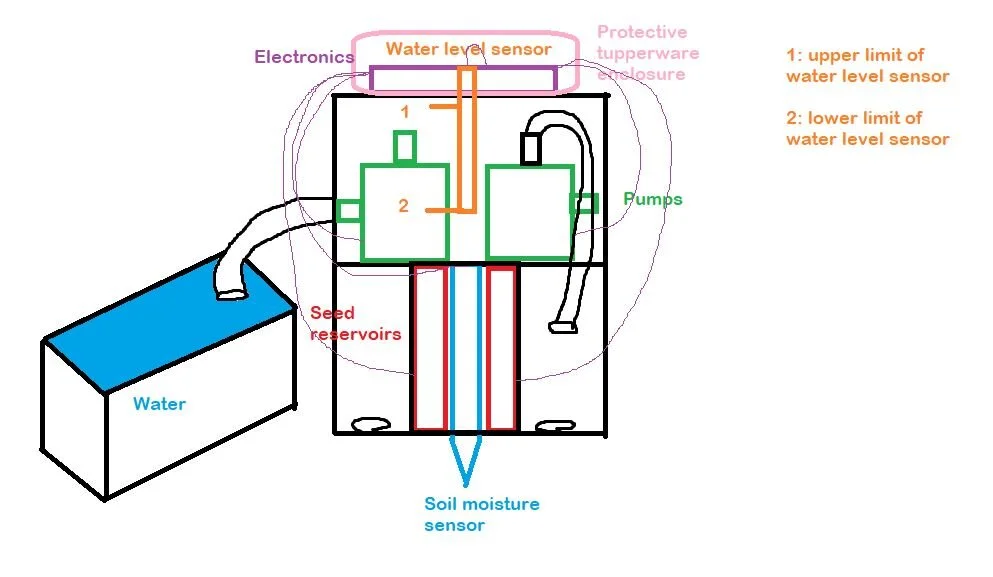

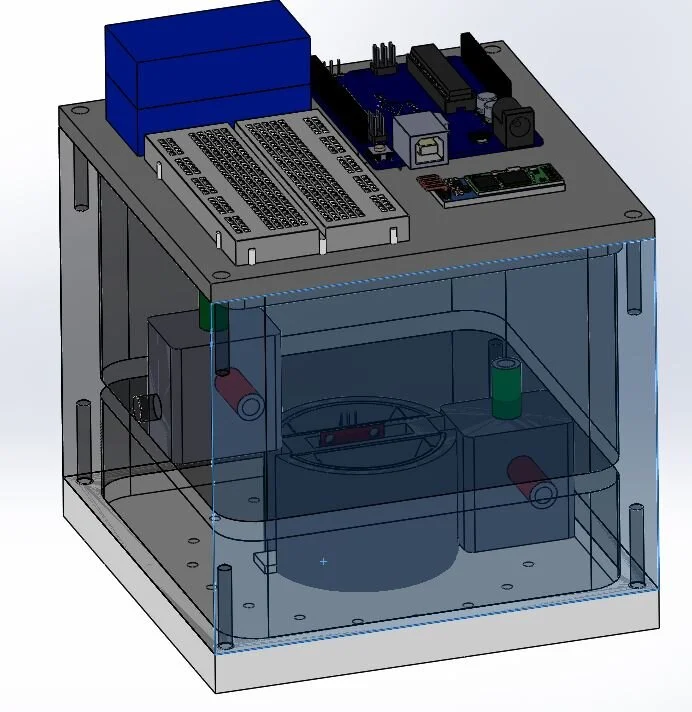

The module body houses two 12V Anself diaphragm pumps that draw water from an external trough into the module and into the sprinkler lid (center right).

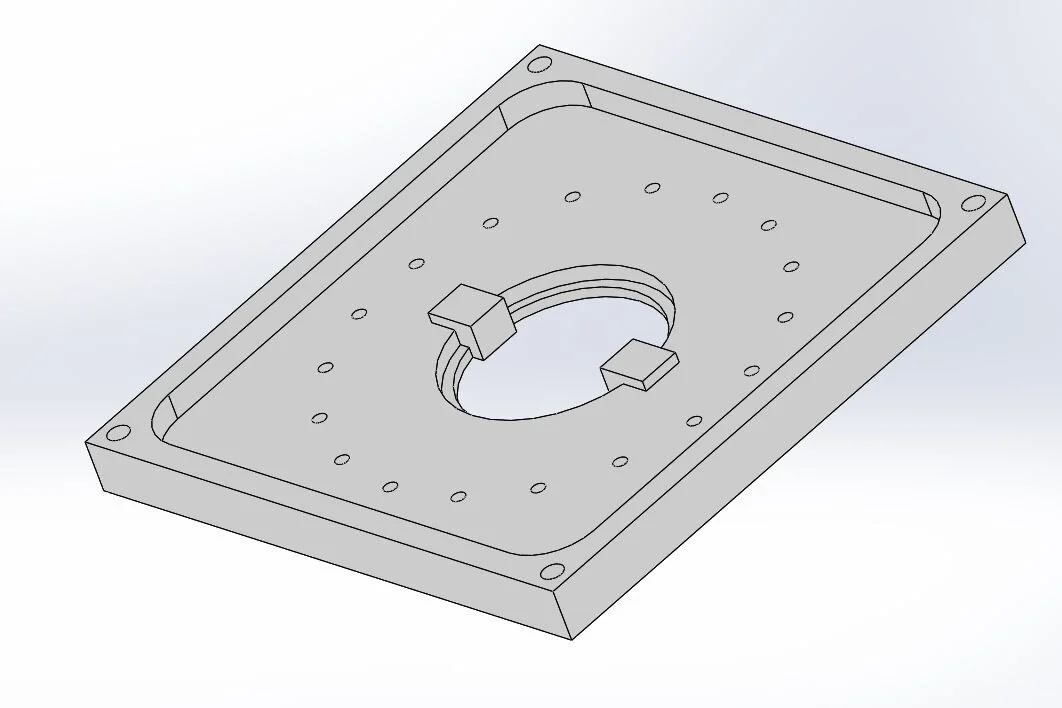

The sprinkler lid at the module base has perforations that allow the influx of water to disperse into a gentler sprinkle.

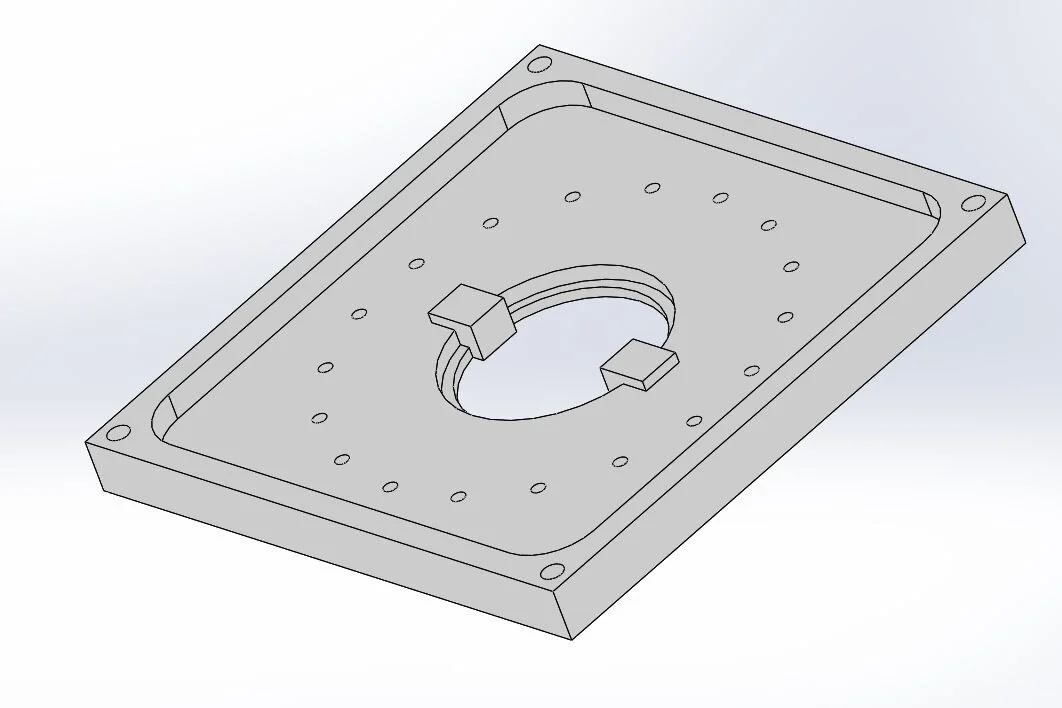

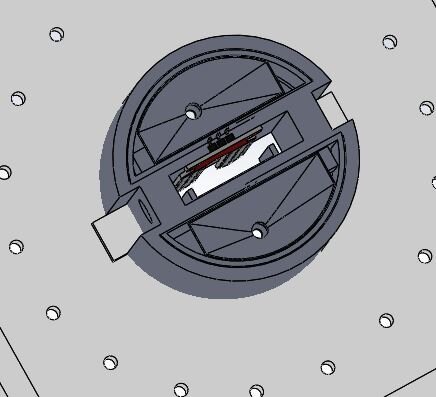

The seed compartment houses the seed dispensing system actuated by small solenoids that act as gate valves, and the soil moisture sensor that protrudes 1” below the module to take humidity readings from the soil.

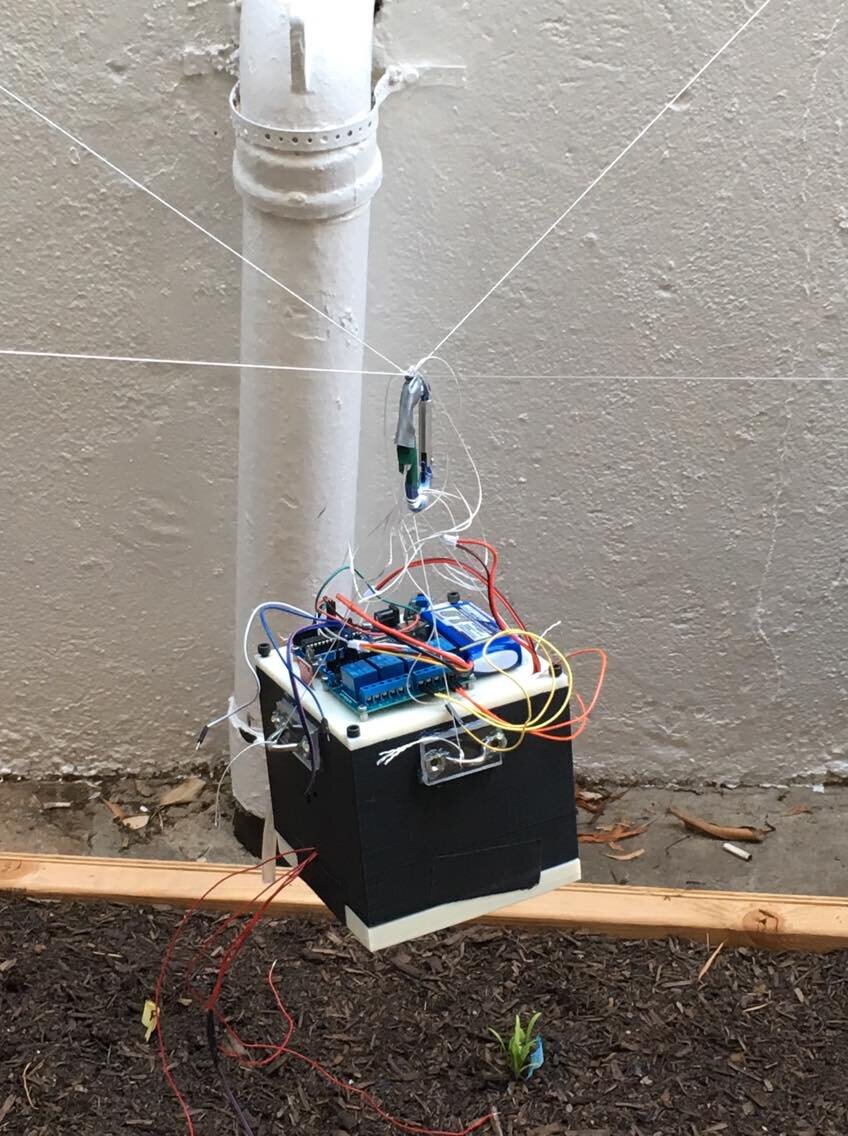

Wiring the module lid. The module is designed to be a water reservoir. Its top lid houses all the electronic components required – 11.1 V battery, relays, Arduino Uno, and BLE modules that allow for communication between the Uno and Mega.

We conducted rigorous experiments using an Arduino Uno and variable voltage supplies to test pump, water level sensor, solenoid, and soil moisture sensors before implementing them into the module. In this scenario, we did volumetric flow tests to test the capability of the pumps and our house design to pull in water from a certain elevation.

We tested the water level sensor multiple times and set an upper limit to ensure that once water filled up the module, the pumps would shut off.

We manufactured the PVC pipe towers and the torsional spring setup using the lathe, horizontal band saw, mill, and Dimension Elite FDM 3D printer. In this picture, I bandsawed Delrin bases for PVC pipe to mount onto.

Building the towers and securing the spool and motor system inside. A failure mode we failed to account for was creating ventilation within the PVC pipes. Two motors failed as a result of overheating. Initially, we didn’t create fins for heat transfer as we wanted to create a waterproof enclosure.

Putting together the spool and motor assemblies on the Delrin blocks, 3D printed mounts, and hex standoffs.

We had the chance to consult with and work with agtech companies and super-gardeners based in the Greater Los Angeles and Bay Area to optimize our system. In the six months we worked on this project, we successfully planted, grew, and harvested 12 spinach plants.