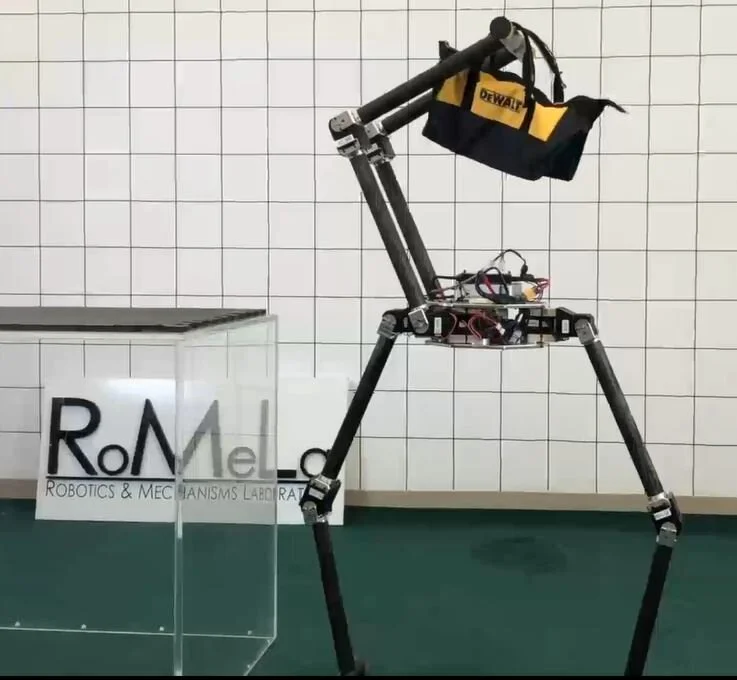

ALPHRED (Autonomous Legged Personal Helper Robot with Enhanced Dynamics) was a humanoid that I had the opportunity to work with Dr. Dennis Hong’s research lab at UCLA. It has four robotics legs with two linear actuators that simulate its body as that of a quadrapod. In this stance, it is in neutral position. As a quadrapod, it maintains high stability and can perform different kinds of creeps, trots, walks, and jogs on flat surfaces and ramps.

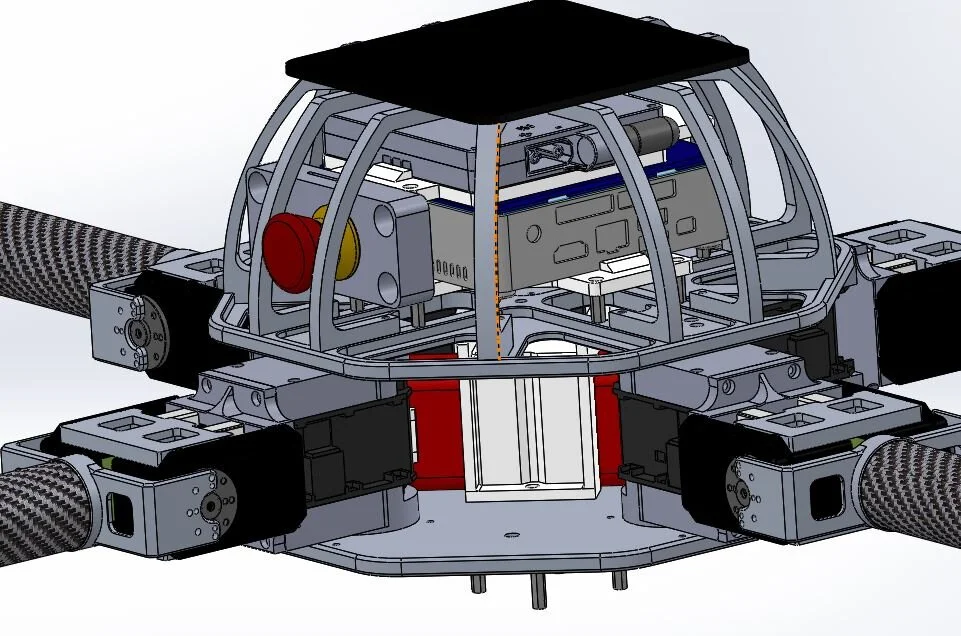

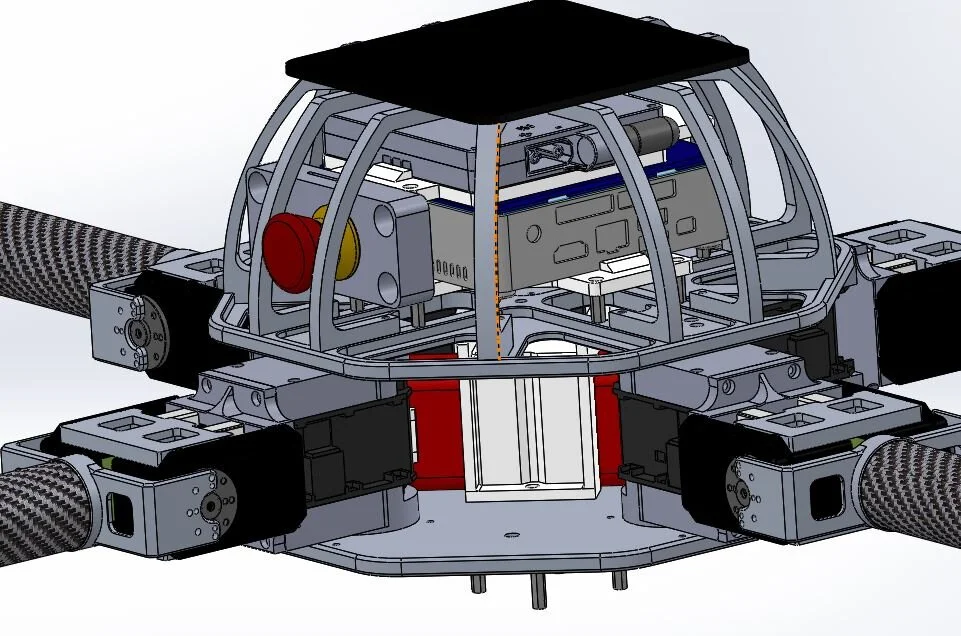

Initially, the electronics packaging was disorganized and unmethodical. Zipties were used to hold the E-stop button and computer and the Lidar NUC in the place. My task was threefold: 1) Design an aesthetic and functional electronics packaging that allows for ease of accessibility 2) Design a rollcage fixture to prevent component damage if ALPHRED falls 3) Integrate a platform for ALPHRED to drop a 1 kg bag on.

I took a pass at designing 3D printed ABS mounts (white) and aluminum curved beam members that would be fastened to the initial faceplate. Performing static and drop test FEA informed me that 12 members was overkill for the application and 4 at the corners would suffice.

All electronic components including the E-stop button and PCs mounted using hex standoffs and 3D printed mounts. Considerations included saving cost and reducing weight.

The underside captures rubber stoppers on standoffs to protect a Intel camera mounted to a ball swivel joint with 3 DOFS and locking mechanism. The camera manually rotates 360 degrees to capture ALPHRED at different angles.

Finally, I used the Wire EDM to fabricate planar aluminum curved beam members for the rollcage fixtures.

The final product with an acryllic plate mounted to the aluminum members for a 1 kg bag to be dropped on, ready for exhibition at Berkeley TechCrunch 2018!

Fast-foward to 6:30 to check out ALPHRED in action at Berkeley TechCrunch 2018!