The 2016-2017 Flagship Battlebot team comprising seven dedicated ASME members built a 60 lb. combat robot (DangerCone) to compete in the Robogames in San Mateo.

The design is unlike any classic bot and consists of shell-spinning elements where the outer steel shells are controlled as both wheels and weapon.

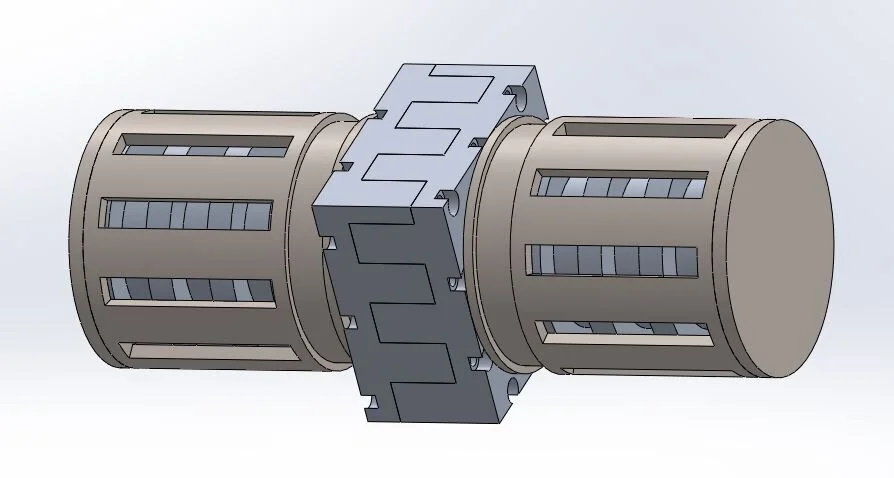

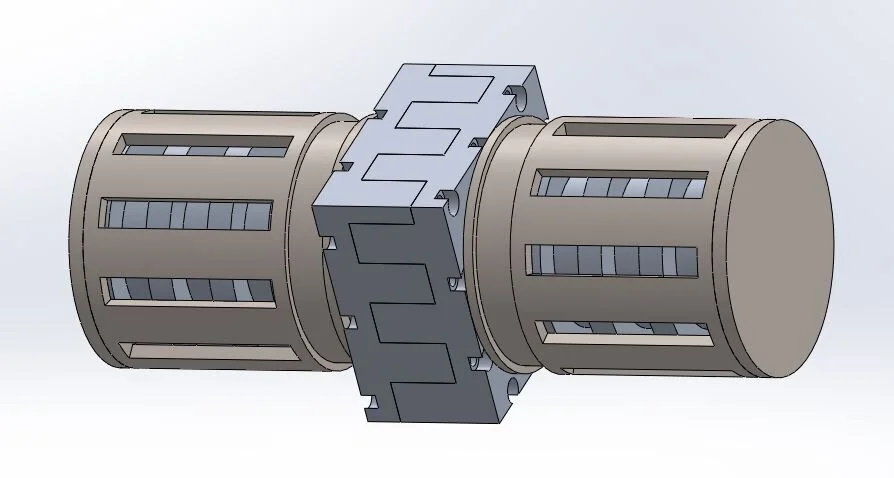

Fully exploded CAD. The bot was expected to achieve top speeds of 1400 rpm and employs a technique called “melty brain control” where translational drift and rotation are controlled while steering the robot in a given direction all on the same drive, as opposed to a robot using a separate drive for motion while the spinning body rotates in a fixed position.

That theory had to be tested though. I was responsible for creating a small scale prototype to simulate “melty brain control” and make design changes.

Winter quarter called for the start of some complex manufacturing! We used a boring bar to bore out a massive 2 ft. tall cylinder of steel and secured it in the mill to begin boring out holes to datum the slots correctly.

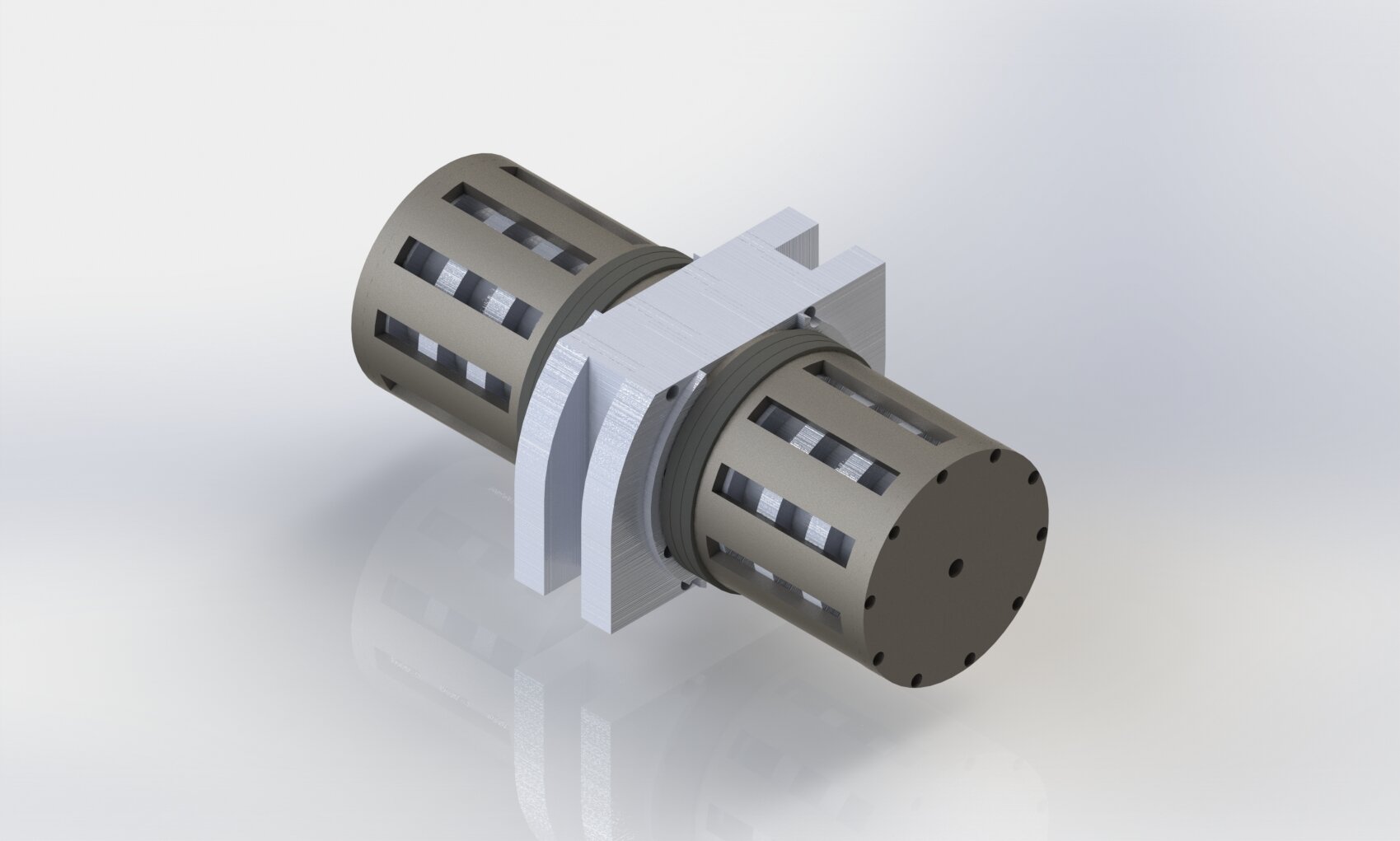

The steel shells as a work in progress. We turned the slot for the rubber treads that would serve as wheels to ensure a tight fit.

In tandem, the parts comprising the aluminum 7075 body, that the steel shells would wrap around, was also bored on the lathe and turned to +-0.005 of the desired dimensions.

The DangerCone full assembled with a view of the inner shafts and bearing assemblies. The center body was designed with a jigsaw locking system and CNCed.